Pipes of large diameters and air ducts, as well as containers, should be insulated with a sheet material made of foam rubber.Armacell Oneflex insulation tubes are designed to insulate pipes with an external diameter of up to 114 mm (AF/Armaflex tubes up to 160 mm, NT/Armaflex and NH/Armaflex tubes up to 89 mm).Pipes of large diameters and air ducts, as well as containers, should be insulated with sheet material made of Armacell Oneflex foam rubber.

For pipes with an external diameter of more than 600 mm, it is required to apply glue to the entire insulated surface

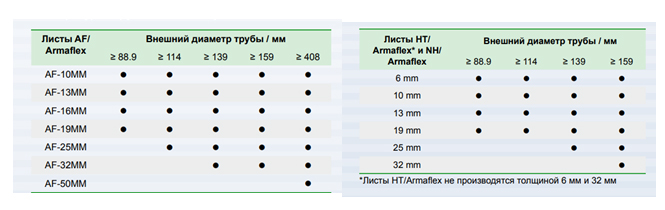

It often makes sense to insulate smaller diameter pipes with Armacell Oneflex sheet material, despite the fact that there is pipe insulation for them. Particular attention should be paid to the correspondence of the thickness of the sheet insulation and the minimum allowable pipe diameter, so that the stresses in the seams caused by the bending of the sheet do not become too large.

These stresses are greater the greater the thickness of the sheet and the smaller the diameter of the pipe. Please check the table below to check the possibility of using Armacell Oneflex sheet insulation of a particular thickness (recommendations may vary for NT/Armaflex and NH/Armafleh).

The degree of stress in the seams is also affected by the ambient temperature during installation.

The characteristics given in the table are indicated for work with Armacell Oneflex sheet material (Armaflex) at ambient temperature ≥ 5 ℃

Following the installation instructions you will properly and reliably insulate the pipeline system and save it from heat loss and condensation formation.

First of all, determine the circumference of the pipe using an Armacell Oneflex strip of the same thickness that will be used for insulation.

Cut out a sheet of Armacell Oneflex of the required size - apply a thin layer of glue to the surface of the edge, let it dry.

Squeeze together the ends of the sheet first, then the middle. Then close the entire seam, starting from the middle part.

To prevent the opening of the seam, make sure that the glue has been applied to the entire surface of the edges of the seam to be glued, and that only the necessary amount of it has been applied. Keep track of the drying time of the glue on the edges, so as not to miss the moment of gluing

Professional and correct installation is the key to durability, energy efficiency and comfortable operation of the system.